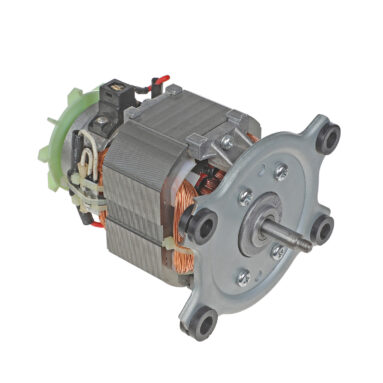

AM95 Series Universal Motor

AM95 Series Universal Motor Models: AM9525 AM9530 AM9535/38 AM9540 AM9545

High Efficiency

Great Torque

High Speed

...

AM93 Series Universal Motor

AM93 Series Universal Motor Models: AM9330 AM9335 AM9338 AM9340

High Efficiency

Great Torque

High Speed

Home &...

AM88 Series Universal Motor

AM88 Series Universal Motor Models: AM8820 AM8825 AM8830 AM8835 AM8840

High Efficiency

Great Torque

High Speed

Home...

AM76 Series Universal Motor

AM76 Series Universal Motor Models: AM7620 AM7625 AM7630 AM7635 AM7640 AM7645

High Efficiency

Great Torque

High Speed

...

AM70 Series Universal Motor

AM70 Series Universal Motor Models: AM7020 AM7025 AM7030 AM7035 AM7040 AM7045

High Efficiency

Great Torque

High Speed

...

AM63 Series Universal Motor

AM34 Series Universal Motor Models: AM6320 AM6330 AM6331 AM6335

High Efficiency

Great Torque

High Speed

Soymilk Mac...

AM80 Series PMDC Motor

AM80 Series PMDC Motor Models: AM8016 AM8020 AM8025 AM8030 AM8038 AM8075

High Efficiency

Great Torque

High Speed

Cl...

AM5260 DC Oil Pump

AM5260 DC Oil Pump Models: AM5260

High Efficiency

Great Torque

High Speed

Oil Pump

Rated Voltage:

DC12V - 24V

...

AM5230 PMDC Gearbox Motor

AM5230 PMDC Gearbox Motor Models: AM5230

High Efficiency

Great Torque

High Speed

Juice Machine

Slow Fry Machine

...

AM44 Series PMDC Gearbox Motor

AM44 Series PMDC Gearbox Motor Models: AM4430 AM4435 AM4450 AM4458 AM4462

High Efficiency

Great Torque

High Speed

Golf Bag ...

AM34 Series PMDC Gearbox Motor

AM34 Series PMDC Gearbox Motor Models: AM3420 AM3425 AM3430 AM3440 AM3450

High Efficiency

Great Torque

High Speed

Multifunc...

Rear Axel Series PMDC Motor

Rear Axel PMDC Motor Models: Rear Axel PMDC Motor

High Efficiency

Great Torque

High Speed

Oil Pump

Rated Voltage:

DC2...

DJ300 Series Self Priming Pump

Pure Copper Motor

Strong self-priming ability, Can quickly exhaust the air in the pipeline

Low power consumption and high-efficie...

DJ302 Series Self Priming Pump

Pure Copper Motor

Strong self-priming ability, Can quickly exhaust the air in the pipeline

Low power consumption and high-efficie...

DJ301 Energy Save Series Self Priming Pump

Pure Copper Motor

Strong self-priming ability, Can quickly exhaust the air in the pipeline

Low power consumption and high-efficie...

Mini Magnetic Electric Series Pump

Household appliances:

Water dispensers, electric kettles, tea sets, champagne machines, cola machines, wine machines, coffee m...

Mini Diaphragm Electric Series Pump

Household appliances:

Water dispensers, electric kettles, tea sets, champagne machines, cola machines, wine machines, coffee m...